Planned and Unplanned Maintenance

Preventative Planned Maintenance

What you get out of your system depends on the care you put into it.

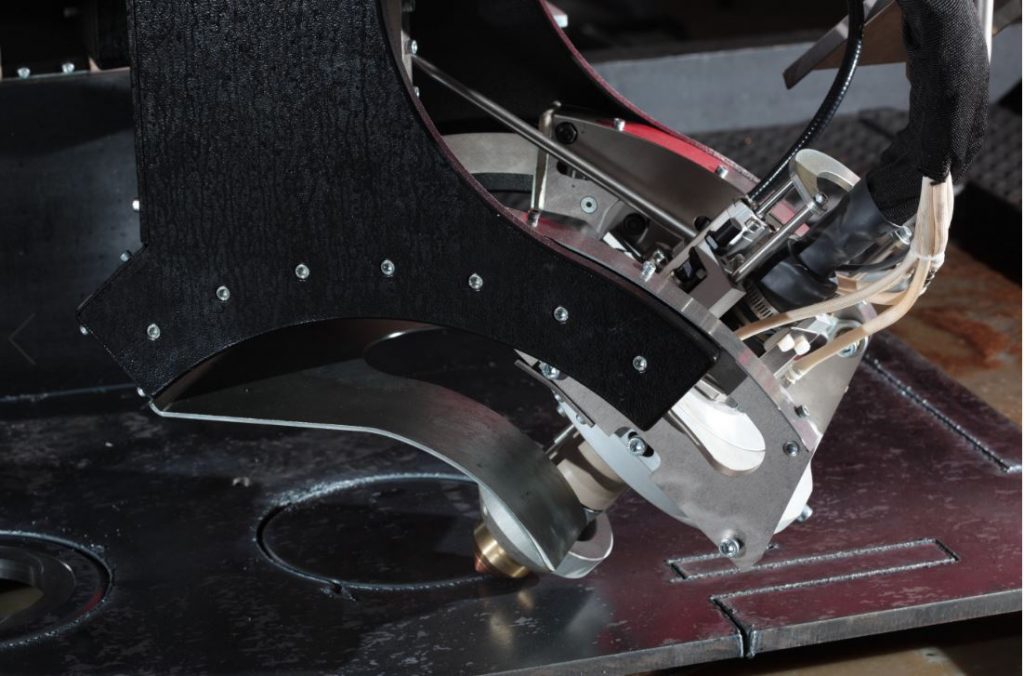

Like any machine, your cutting machine system requires care to operate at peak performance.

You can ensure that happens with NC Technologies Preventative Maintenance programs. It’s the smartest and most efficient way to optimize output, reduce unplanned downtime and minimize the operating costs of your cutting system.

We keep it productive

Nc Tech preventative maintenance reduces the likelihood of emergency repairs. Which is ideal. After all, if your cutting machine isn’t productive, you’re not productive. Its the best way to get ahead of potential problems and keep your operation running smooth.

We keep it simple

NcTech preventative maintenance isn’t complicated. Our program is an easy to use comprehensive package that includes:

- A periodic maintenance and cleaning plan

- A schedule of replacement for common wear items

- A full system inspection

- Training on the recommended periodic maintenance for your particular system

- Maintenance schedules based on application specific and environmental conditions

- Part replacement schedules based on actual machine configuration and usage

We keep it genuine:

To make sure your system achieves optimized performance, we always use genuine Hypertherm parts engineered to the highest level of durability and reliability so there’s no degradation in cutting quality or system life.

Unscheduled Maintenance – Breakdowns

Machines and their cutting systems break down, it happens. At NcTech we try to avoid breakdowns so there’s less unexpected downtime with our preventative maintenance and on site training. However if your machine does breakdown we’re here to get you back up and running as quick as possible. We have trained technicians to fix your problem promptly.

Call us now to get your machine back up and running.

Unscheduled Maintenance – Machine Breakdowns, Plasma/Laser/WaterJet/Oxy Breakdowns

When your machine breaks down you’re losing money. Here at NcTech we have seen many breakdowns before and thus we know how to tackle your problem. If it’s a broken motor, a collapsed bearing, or you just can’t turn the machine back on we are here to help. If the problem is urgent call us immediately, if not please feel free to make an inquiry.